Want to know how a classic Idaho beer is made? See inside Boise’s Payette Brewing Company

I’ve spent my fair share of summer afternoons in Payette Brewing Company’s beer garden, enjoying glasses of IPAs, pale ales and sours while thoroughly beating my friends at cornhole.

The cornhole set is typically found at the back of the garden, past the newly built fire pit and a few rows of benches. It sits next to a large, inconspicuous building at the back of the brewery that I always assumed was storage.

The brewery’s tap room is spacious and airy, with long tables and an expansive bar at the far end opposite the front doors. One wall of the tap room is dominated by large fridges stocked from top to bottom with neatly placed six-packs showcasing Payette’s many beers, available to buy for those who couldn’t get enough while at the brewery.

It doesn’t get much better than Payette when it comes to breweries near downtown and right off the Boise Greenbelt.

But what never crossed my mind was that the brewery operation itself — the brew system, fermenters and packaging machinery — is right behind the tap room. Unless you notice the two grain silos hiding around the back of the building, you might never suspect it.

All that time I was playing cornhole next to the building that I naively thought was storage, I was just feet away from one of Payette’s massive giant fermenters, which hold up to 60 barrels of beer. Yes, I understand logically that the brewery for Payette Brewing Company would be on-site, but I’m usually just focused on my beer.

I know this now because, in February, I was lucky enough to receive a behind-the-scenes tour with Paige Francis, marketing and art director for Payette Brewing. She invited me to the brewery for a tour after I casually mentioned that Payette’s Sofa King Sunny Hazy Pale Ale is one of my favorite local beers in a story I wrote about finger steaks and ice cream potato.

After a 45-minute tour, in which I managed to meet the lead brewer, cellarman and founder Mike Francis, I can confidently say that I could now brew a beer from scratch. (OK, that might be a lie, but I know more about brewing than I did before the tour.)

While I could run you through that whole process, here are some highlights I took from the experience.

You can see the brewing operation yourself

Although customers can’t just walk around the brewery willy-nilly, a mezzanine looks over the vast room that was once the Bronco Elite Gymnastics gym. Payette Brewing moved into the building almost seven years ago after moving from its original location in Garden City.

“So the tap room, when it was Bronco Elite, was a swimming pool. This room was a gymnastics floor,” Paige Francis told me as we stood on the viewing deck overlooking the brewery.

“The side bays where we have fermenters were racquetball courts,” Francis continued. “And then, where we’re standing, this was a track that went around the whole room. The office, which is on the other side of the tap room, was where there was like a day care and dance classes and stuff.”

A massive U.S. flag still hangs from the ceiling from the building’s days as a gym. The mezzanine is open for customers during opening hours and can also be rented out for events.

Technology!

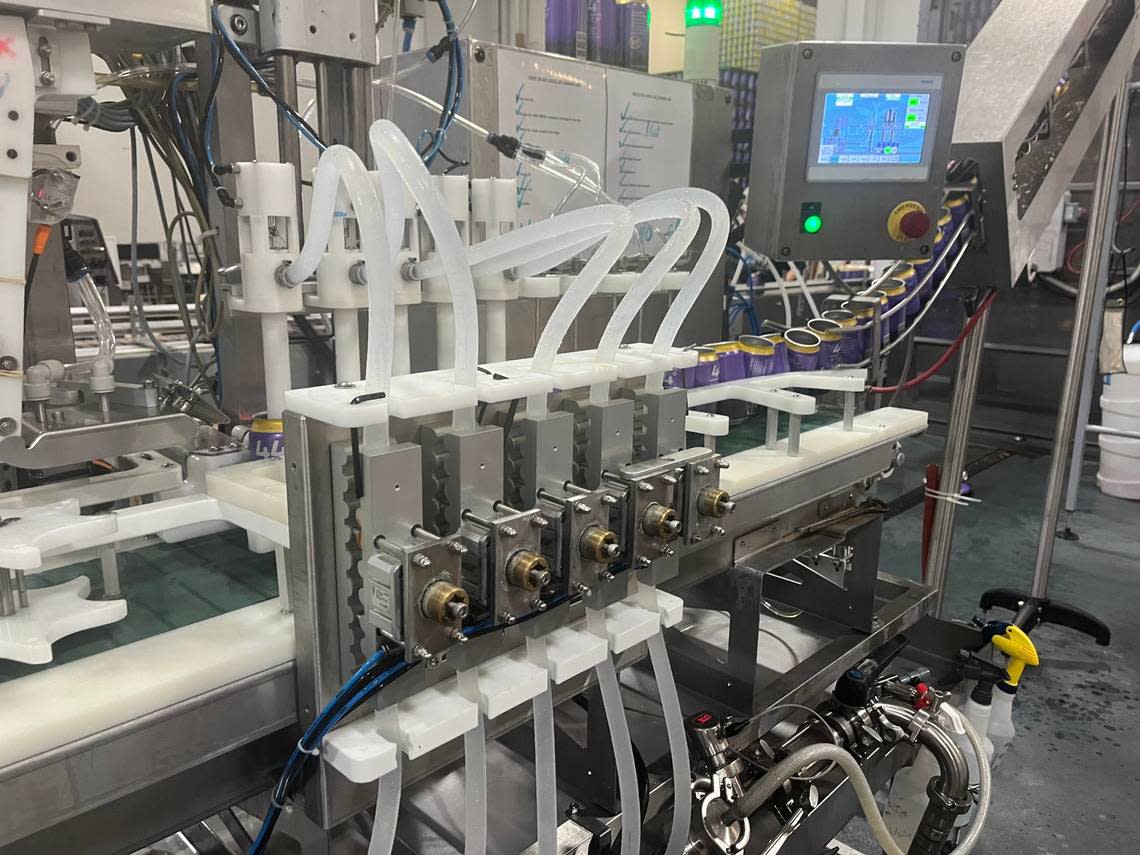

I truly entered the brewery’s heart when Francis led me up a set of stairs to a platform with four giant containers essential to the brewing process: the brew system. It’s a complicated process, and I know I promised I wouldn’t break down the whole operation, but I found it intriguing, so you get to learn about it, too. Here’s the TLDR:

The grain from the outdoor silos is brought inside and put in two hot liquor tanks that help crack open the grain. The grain is then transferred to the brew system and, in the first tank, is combined with hot water that pulls the sugar enzymes out of the grain, creating sugar water and making the grain resemble oatmeal.

The mix is then transferred to the next tank, where the liquid is separated from the grain and moved to the next container. From there, flavors can be added to the liquid, such as hops and fruit. Finally, the soon-to-be beer is transitioned over to the fermentation tank, where additional flavors can be added, and it’s kept at a specific temperature, depending on the type of alcohol, for several weeks.

But here’s the hitch: The whole process is done with the tap of a touch screen.

Lead brewer David Torres had just finished making a new imperial IPA when I visited. It was already being served in the tap room, so naturally, I had a taste — it tasted more like a cider with a white wine or champagne tint than a classic IPA.

“It’s a very easy-drinking beer for people who don’t really like the regular beers that everyone else does, like the heavy IPA stuff,” Torres said. “So yeah, we gave it some flavor.”

From Boeing to Brewing

Mike Francis acknowledges that he should have been much more frightened than he was when starting Payette Brewing at age 27.

“I was an engineer at Boeing but getting into beer,” Francis said. “Part of me wanted to move home, I lived in Seattle, and Boise is home. So I wanted to jump into it, and I was just young enough and dumb enough to think it was a good idea.”

As it turned out, it was a good idea. Payette Brewing distributes beer throughout Idaho and to every state the Gem State borders. While I chatted to Mike, towering opposite us was palette upon palette of filled beer cans of all different colors.

Each palette holds 8,169 cans, and there were about 70 palettes in the brewery as we spoke. That’s over half a million cans of beer waiting to be sold and drunk.

After over a decade of operation in the Treasure Valley, Payette is one of the most popular breweries in Idaho and can be found in most Boise stores and bars.

“Where it hits is when you’re out in a bar or restaurant, and you hear someone talk about Payette or something, it’s like ... wow,” Mike Francis said. “Especially when I’m just sitting there having a beer, and I hear someone say something cool about Payette, it’s really awesome. It kind of justifies what we’ve been doing.”