Vermont 'Tech Hub' working on proposal to land $35 million in federal funding

A critical deadline is fast approaching for the University of Vermont, GlobalFoundries and the state, which last October celebrated landing designation as a Tech Hub by the U.S. Department of Commerce's Economic Development Administration (EDA), one of just 31 in the country.

The designation − won out over nearly 400 applications − came with exactly no money. But on Feb. 29, Vermont's tech hub, led by Doug Merrill, regional innovation officer at the University of Vermont, will submit a proposal to the EDA for a $35 million grant to get the Tech Hub up and running.

"We're competing with 20 other Tech Hubs," Merrill cautioned. "It's not assured (that we'll get the grant) but I think we have a great story and really good partners."

The Tech Hubs program was authorized by the CHIPS and Science Act signed into law in August 2022 to bolster the semiconductor industry in the United States with billions of dollars of federal investment in all regions of the country. The act designated $10 billion for the Tech Hubs program alone, the point of which is to spread the semiconductor wealth into rural areas like Vermont.

"For too long, economic growth and opportunity has clustered in a few cities on the coasts," the White House said in October. "Tech Hubs awardees were selected to represent the full diversity of America, selected from more than 370 applications spanning 49 states and four territories."

The White House estimated that nearly 75% of the money designated for Tech Hubs will go to small, rural "historically underserved" communities. Tech Hubs encompass 32 states and Puerto Rico. In the Northeast, there are Tech Hubs based in Rhode Island, New Hampshire, New York, and Maine, in addition to Vermont.

It's nice to have a semiconductor fab to include in your proposal

It certainly didn't hurt Vermont's tech hubs proposal to have a semiconductor fab in Essex Junction − GlobalFoundries − that happens to be focused on advancing a chip based on a material called gallium nitride, rather than the traditional silicon.

Gallium nitride (GaN) was at the heart of UVM's winning proposal. The innovative material promises better performing chips for a range of industries, from electric vehicles to medical imaging equipment and consumer electronics.

Scott Johnson, senior director of technology development at GlobalFoundries in Essex Junction, said the fab is working with GaN in two areas: power converters and RF (radio frequency) communications. He said in RF communications, a GaN transistor can provide higher frequency and a stronger signal from any personal device such as a cell phone, or from infrastructure such as cell phone towers, supporting 5G "and beyond."

"Because it's more efficient, (GaN) can do this at a lower power, so your battery will last longer," Johnson said. "GlobalFoundries works with companies that design chips that go into communication infrastructure and your phone. We're already deep into the chip business in both those areas. About 85% of phones have a GlobalFoundries chip in it. Going forward, we'll be adding GaN chips in your phone."

Johnson believes GaN chips will also make better, more efficient power converters for the EV industry and others. Power converters are used to switch voltage on and off and to switch from AC power to DC power, both critical functions for electric vehicles.

"Silicon has a difficult time getting that done," Johnson said. "The converters are large and waste power. Moving to GaN, the size can be reduced, making it lighter and cheaper, saving energy so your car gets more mileage for the charge."

Hello, Department of Commerce. Here's what you get for your $35 million.

Merrill said the Vermont GaN Tech Hub proposal lists six elements for the $35 million it's seeking from the Economic Development Administration:

A design center with the software tools required to design GaN devices. The tools allow engineers to design, test and lay out their circuits on a substrate (again, GaN) for prototyping. Normally it costs up to $300,000 per year to license the tools, but tech hub members will get access at "very low rates," according to Merrill.

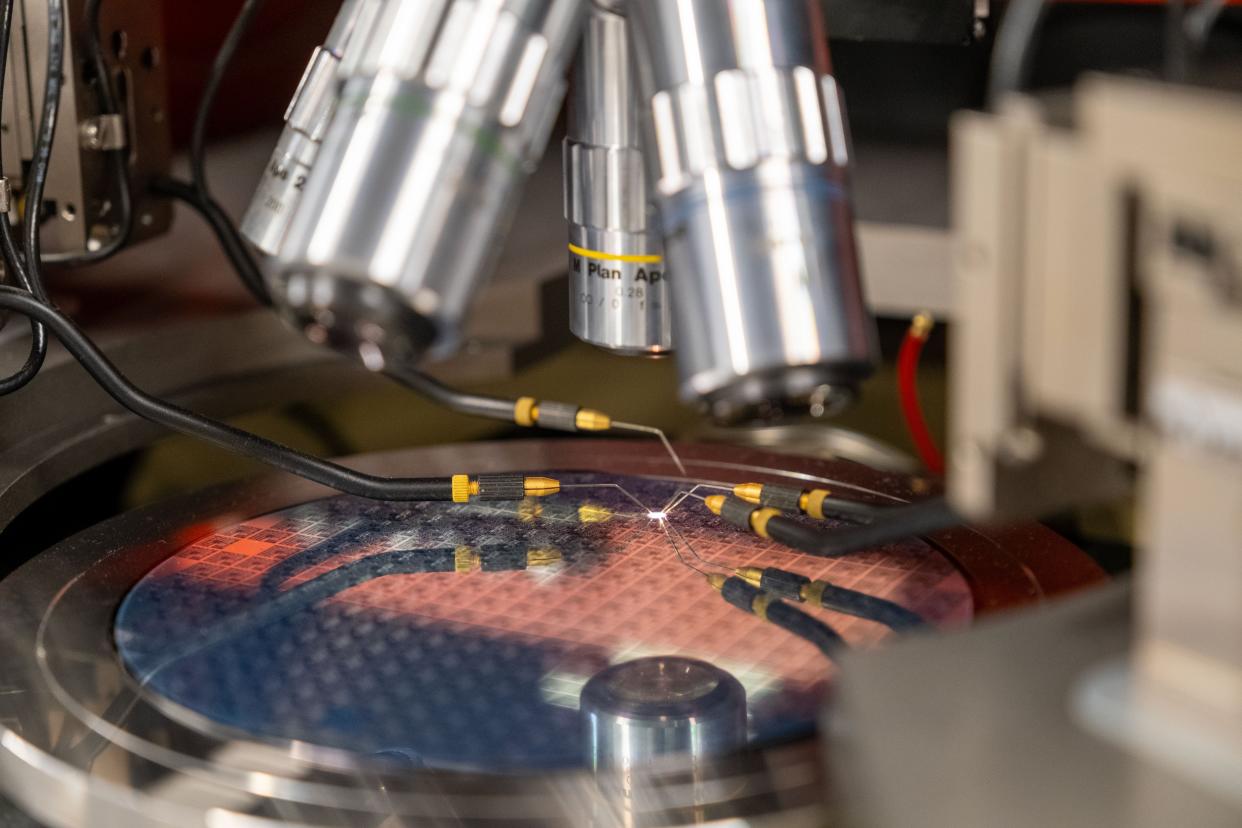

A prototyping center at GlobalFoundries. Merrill said the fab has committed to running a load of wafers through their facility three or four times a year dedicated to prototype projects from local companies and local educational institutions. There are dozens of steps involved and it will take 60 to 90 days for the wafers to get through the entire fab, according to Merrill, but it gives access to the fab that local companies don't currently have.

A characterization lab at OnLogic, in their new facility in South Burlington near Interstate 89. Merrill explained that once the GaN devices are produced at GlobalFoundries, they'll go to the characterization lab for inspection and testing to determine if they're actually doing what they're supposed to do. OnLogic, which makes industrial computers for ATMs and other applications, is providing the space for the lab for a nominal fee and helping manage it.

Workforce development at UVM's Professional and Continuing Education (PACE) program. Maureen Hebert, director of employer partnerships will be coordinating with Community College of Vermont, the Vermont State University, including Vermont Technical College, the Vermont Manufacturing Extension Center, Dartmouth College and Norwich University to funnel people into the semiconductor workforce. Hebert will target the gamut of prospects, from those with high school diplomas for industry apprenticeship programs to people getting their doctorates in semiconductor research.

An "exemplar project" from Resonant Link, the South Burlington-based company that makes wireless charging systems for industrial applications and medical devices. Merrill said the GaN device being proposed by Resonant Link serves as an example of what the Vermont GaN Tech Hub will be able to produce when it's up and running.

Administration, consisting of Merrill's organization, which will operate the tech hub.

Once the Vermont GaN Tech Hub proposal is submitted on Feb. 29, Merrill said it will take until June or July to get a response.

"If it's positive, we will begin ramping up all these activities, and we'll see the tech hub begin to function as an operating organization," he said. "Probably a year from now, in January 2025, we'll have the prototyping center open and the software center open. We'll be ready for people to start designing projects and putting them through prototyping."

Merrill stressed that all the projects have to be based on using gallium nitride. He said he will listen to pitches from companies, which will then go to a steering committee to determine whether the tech hub wants to put resources into the project.

Tech hub will tighten the bonds between Vermont's high tech businesses and the University of Vermont

Merrill was sought out by UVM to run the tech hub because of his resume. After graduating from Cornell University with an engineering degree, he joined General Electric's manufacturing management program, working on everything from steam and gas turbines to solar panels, and overseeing the construction of a gas turbine plant in China for GE.

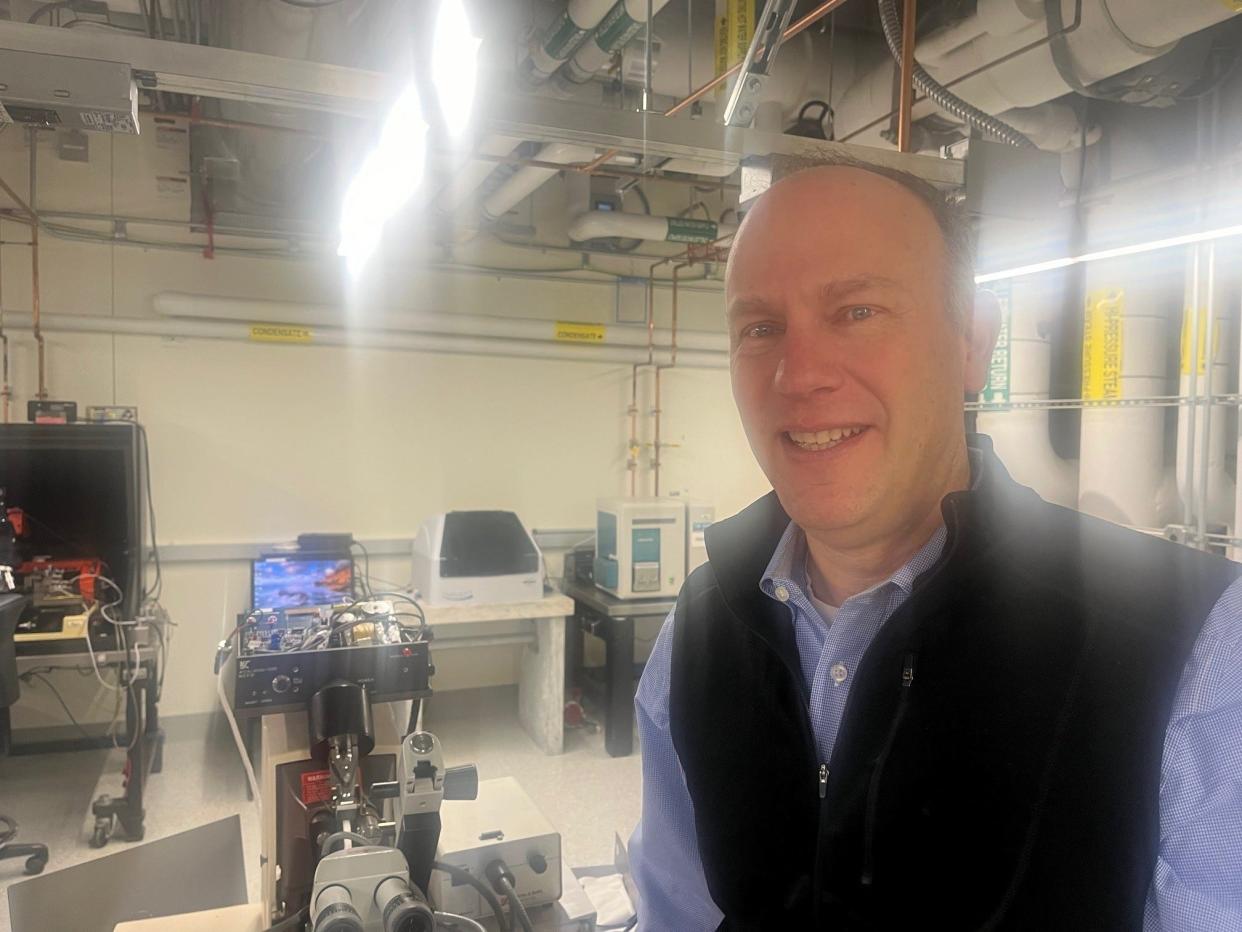

Merrill left GE in 2005 to run the Husky Injection Molding plant in Milton, but left there in 2008 after a private equity firm took over the company. For the next eight years, he worked as a consultant for local companies, then worked as operations manager at DynaPower in South Burlington for a year before leaving to run SemiProbe in Winooski, a semiconductor test equipment company. After leaving SemiProbe a year and a half ago, Merrill, 56, tried his hand at semi-retirement, but failed.

"I like to ski and I like to mountain bike, but I got bored," Merrill said.

Then the call came from Kirk Dombrowski, vice-president of research at UVM, asking him to run the tech hub. Merrill thought it sounded like a great opportunity, especially since he had already been talking to Dombrowski about how UVM's engineering school could interact "more completely" with local technology businesses.

UVM has a device characterization lab up and running in Discovery Hall on campus where engineering students can work hands-on with semiconductors and wafers. Most of the testing equipment was donated by GlobalFoundries.

GaN is perfect for local wireless charging company looking for faster, smaller, more efficient products

Resonant Link is at the heart of Vermont GaN Tech Hub's proposal for funding, with its "exemplar project" of a GaN-based device.

The wireless charging company has four co-founders, all of whom hold doctorate engineering degrees. Three of the partners − Chief Executive Officer Grayson Zulauf, Chief Technology Officer Aaron Stein and Chief Science Officer Phyo Aung Kyaw − met at an industry conference in Italy in 2018 and decided to start the company. The fourth co-founder, Charles Sullivan, is a professor at Dartmouth Engineering School in Hanover, New Hampshire.

Resonant Link has its headquarters and a manufacturing operation in Technology Park in South Burlington, but also has employees and facilities in the Bay Area, Boston and Zurich, Switzerland. There are about 50 employees total, with half in Vermont.

Tate Krasner, director of government programs, said Resonant Link has "game-changing" technology, developed by Sullivan at Dartmouth, whom both Kyaw and Stein worked with; Kyaw as a PhD student and Stein as a post-doctoral fellow.

"Our differentiator is our coil design that allows us to create an electromagnetic field to transfer power wirelessly five to 10 times faster and more efficiently than existing technology," Krasner said.

Wireless charging is a huge advantage for medical devices implanted in the body

Resonant Link began working with pharmaceutical giant Abbott in 2019 on a fully implanted left ventricular assist device that could be charged wirelessly rather than using wires implanted in the body, which can lead to infection. The ventricular assist device is a surgically implanted mechanical pump that helps the left ventricular − the main pumping chamber of the heart − pump blood to the body, according to Stanford Medicine. It's used in patients who have reached end-stage heart failure. For other medical devices, Resonant Link's wireless chargers would prevent the need for patients to undergo surgery to replace the batteries.

Today, Resonant Link is working with 28 different medical device companies on wireless charging for devices ranging from spinal cord stimulators to alleviate chronic pain to brain-computer interfaces that will help restore motor function and salivary diagnostics that replace slow, painful diagnostic testing with a device implanted on a person's tooth, similar to a crown. The device monitors saliva for signs of diseases such as throat cancer.

Rachel Allard, senior director of marketing, explained Resonant Link works with companies like Abbott to develop charging systems for their devices that are easy to use and convenient. The systems could be incorporated into a vest the person wears, or into a pillow for overnight charging.

"Every customer has a different way they've designed it," Allard said of the charging systems. "It's really flexible."

Resonant Link is making charging safer and faster for forklift operators everywhere

Resonant Link's other major area of focus is fast wireless charging for industrial EVs such as electric forklifts. Allard said the company is working with a dozen clients, including the top forklift manufacturers in the United States and large warehouse operators.

The charging is automated, utilizing a charging station and a receiver mounted on the forklift or other piece of equipment. The receiver tells the charging station when it needs power and how much it needs, without involving a human being. Jon-Rene Bilodeau, manufacturing operations lead, explained why that's important.

"People focus on the convenience of (wireless) charging, but it also plays a huge part in the safety portion of it as well," Bilodeau said. "I don't know if you've ever been in a manufacturing environment, but with traditional electric forklifts someone has to get off, put on (personal protective equipment) and plug into high power. This will help eliminate that, taking the technology to the next level."

Krasner said Resonant Link is already using off-the-shelf GaN chips in its devices because of the greater efficiency they bring, but now, thanks to the tech hub, the design, development and fabrication of custom GaN chips to make its wireless chargers even better is possible.

"Unless you have partnerships in place, it doesn't actually happen," Krasner said. "I think this is a unique opportunity."

Contact Dan D’Ambrosio at 660-1841 or ddambrosi@gannett.com. Follow him on X @DanDambrosioVT.

This article originally appeared on Burlington Free Press: Vermont is home to one of just 31 U.S. Tech Hubs designated by feds