This Tiny Modular Nuclear Reactor Just Got the Green Light From U.S. Regulators

The U.S. Nuclear Regulatory Commission (NRC) has awarded approval to nuclear leader NuScale for its small, modular reactor design.

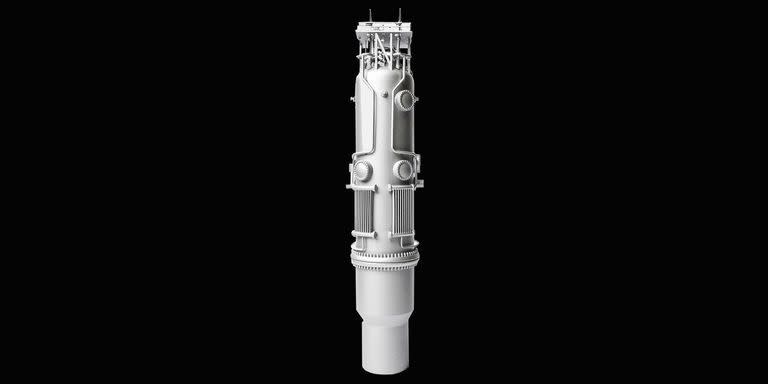

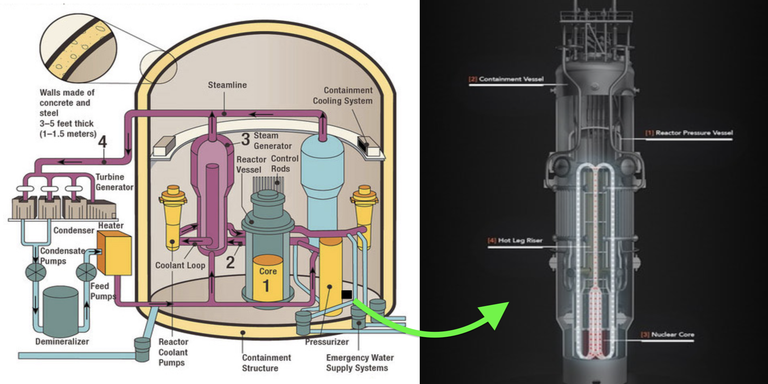

These reactors will be built offsite and installed onsite at nontraditionally small nuclear plants.

The energy industry faces huge challenges before it can decarbonize.

In a major step forward for the burgeoning modular nuclear reactor movement, the U.S. Nuclear Regulatory Commission (NRC) approved all but the final formalities on a tiny reactor design put forth by industry leader NuScale. The July 29 announcement comes after six years of steady work toward regulatory approval.

The combination of small and modular is new for nuclear energy. Decades ago, the first nuclear plants were small because that was simply the limit of the emerging technology at the time. Modular design concepts were in the mix back then because, honestly, what wasn’t in the mix? There were even nuclear-powered concepts for family sedans as far back as the 1950s.

NuScale, based in the suburbs of Portland, Oregon, has been working on its small, modular reactor concept for over 15 years. The company began in the early 2000s with funding from the United States Department of Energy that merged the interests of multiple universities and government laboratories—something very common in the energy sector and in scientific fields like physics. Then, in 2007, NuScale went solo and took its show on the road to begin the long slog toward nuclear regulatory approval; the process began formally in 2016 with NuScale’s initial application for its modular reactor design.

“The NuScale team spent over 2 million labor hours to develop the information needed to prepare the design certification application, which included 12,000 pages, 14 topical reports, and had over 2 million pages of supporting information,” Diane Hughes, vice president of marketing and communications for NuScale, tells Popular Mechanics by email. “In turn, the NRC spent over a quarter-million staff hours reviewing the application. That said, the NRC review process took 42 months, which was the fastest design review in the NRC’s history.” Hughes attributes this feat to NuScale’s simple design.

In its announcement, the NRC explains that NuScale’s small, modular reactor is just the seventh reactor design ever to be approved for use in the U.S. It’s also the first design to be modular. To understand what a big deal that is, we have to take a step back and consider how other nuclear power plants have been built.

I grew up in the shadow of the Byron Nuclear Generating Station outside Rockford, Illinois. Construction of the plant took a decade on a site that is about a mile-and-a-half square feet. The plant was planned around the site, not vice versa—where can we put a plant that is far enough outside of town, that has naturally flowing water, with enough room for over 700 employees and all the safety equipment and redundancies we need? What reactor can we build there?

That giant power plant has run for nearly 40 years and has supplied consistent power to about two million homes in northern Illinois. Even so, it’s embroiled in a licensing and renewal controversy, at least partly because the future of nuclear energy, and of energy more broadly, is a big question mark right now. Nuclear energy is considered unfavorable by many people around the world, and not without reason: several high-profile disasters hurt public opinion for decades, and now many of the plants from the “nuclear boom” of the 70s and 80s are aging out of service, becoming albatrosses.

But advocates say that there is simply no other way to replace the bulk of the world’s current fossil-fuel energy. If we’re going to stop burning coal and natural gas at power plants, we need something else, and renewable energy simply can’t account for everything. Renewables aren’t right or accessible for every community that is in need of a decarbonized energy solution. This is the market in which small, modular nuclear reactors have arrived.

“Especially while the global community is suffering from crises like volatile energy prices and climate-driven extreme weather events, the need for carbon-free energy solutions like NuScale’s small modular reactors has never been greater,” Hughes says. “While European gas futures have soared to new records, nuclear fuel prices are and have been much more stable as compared to natural gas prices. Achieving climate goals simply cannot be done without nuclear energy as part of the equation.”

NuScale is certainly not alone in the marketplace of ideas when it comes to small, modular nuclear reactors, but it’s had one special advantage all along: its design is revolutionary in some ways, but still built on the basics of water-cooled, nuclear power generation. Like Byron, a NuScale power plant will be cooled by a pool of fresh water. But that water will circulate and be cooled and reused rather than flushed out in quantity; NuScale says the reactors can still run almost indefinitely without pumps.

With the regulatory approval in hand, NuScale will finally be able to plan its first plants in the United States. These are still subject to location-based approval, especially because nuclear plant regulations are still based on huge sites like Byron. But NuScale’s reactors won’t be made on site. They’ll be made in factories and brought onsite in pieces for final installation and activation.

“Potential customers from numerous countries have expressed interest in our technology, and we currently have 18 signed and active memorandums of understanding with customers in 11 countries interested in, and considering, a deployment of a NuScale power plant,” Hughes says.

You Might Also Like