Fate of Hickey Freeman Factory in Question as Samuelsohn Owner Shifts to New Brand

One of the last remaining American manufacturing plants is in a state of flux.

At the end of May, the license for Hickey Freeman tailored clothing will be moving from Samuelsohn to Peerless Clothing and with it, the production of the collection in Rochester, New York, where it had been made for more than a century.

More from WWD

The Hickey Freeman label is owned by Authentic Brands Group, which awarded the North American license to Peerless in January. Peerless also holds the license for other Authentic suit brands including Hart Schaffner Marx, Van Heusen and Shaquille O’Neal XLG.

When the switch becomes final this spring, Peerless will begin manufacturing the Hickey Freeman collection outside the U.S. The line will be introduced in the fall and will feature a half-canvas make and felt sleeve stitching. It is launching at Dillard’s and prices will drop dramatically, with suits retailing for $595 to $795, rather than $1,700 or more.

The new messaging is: “An American heritage brand evolved for the modern traditional customer,” said Dan Orwig, president of Peerless, who added that his company’s mission is “to preserve and evolve an iconic American heritage brand to service the modern traditional customer, offering timeless styles at competitive prices, through innovative design and manufacturing practices.”

As a result of the switch, the Hickey Freeman Tailored Clothing plant in Rochester, which was built in 1912, is being renamed and Samuelsohn’s chief executive officer is seeking a company to take over its long-term lease to produce clothing for other brands at the plant.

Stephen Granovsky, chief executive officer of Luxury Men’s Apparel Group and Grano Retail, which owns Samuelsohn, Culturata, Lipson Shirtmakers and other brands, had purchased the factory from Doug Williams, the one-time chief of Hart Schaffner Marx and Hickey, in 2013.

Granovsky, in turn, sold the factory last June to Home Leasing, a real estate development firm, which made a deal to build 134 affordable senior housing units on some two-thirds of the 225,000-square-foot, four-story plant site. The development will be renamed Tailor Square and the project is receiving $70 million in funding from the state of New York for the conversion.

As part of the deal, Granovsky signed a long-term lease with Home Leasing to retain 77,000 square feet for the Hickey Freeman Tailored Clothing facility.

In June, he said, the plant will be renamed Rochester Tailored Clothing and he’s negotiating with two potential companies to transfer his lease. Some 80 percent of the merchandise produced at the factory today is for other brands such as Brooks Brothers, Todd Snyder, Haspel, Hart Schaffner Marx and J. Press, he said.

“No one else makes a quality garment in the U.S. with any scale,” Granovsky said. But the Rochester factory’s ability to make high-end garments “attracted some interest so we decided to market it to other strategic partners.”

Granovsky declined to name the companies he’s talking to about buying the plant, citing confidentially agreements, but the options are limited. One name that has been floated is Tom James, a Tennessee-based custom clothing manufacturer whose sister brands include Oxxford Clothes, Coppley, English American, Holland & Sherry, Gitman Brothers and Individualized Shirts.

Todd Browne, CEO of Tom James, did not return calls seeking comment.

While Tailored Brands owns the factory in New Bedford, Massachusetts, that makes the Joseph Abboud brand, it is not believed to be interested in adding more production.

Speculation also centered around U.S. manufacturers that produce garments for the military that could be open to contracting with the Rochester factory.

Depending upon when and if a deal can be struck, Granovsky said if that company “wants to continue production for our customers in Rochester, then it will stay. If not, we will work with each customer to consider a move to Montreal production if they so desire.”

He said he expects to have more clarity on the situation in the next 60 days.

Granovsky’s quest to transfer his lease at the Hickey factory comes after a series of challenging years for the facility. The plant now employs just over 200 people, about half the number who worked there in 2019 when Granovsky appeared with New York state’s then-Lt. Gov. Kathy Hochul at the plant to celebrate the addition of 80 jobs and the acquisition of a $4 million loan to upgrade the facility. At the end of 2018, U.S. Sen. Charles E. Schumer further assisted the company by providing Hickey with up to $3 million a year in tariff relief to help it compete with overseas producers. And in 2021, Schumer again stepped in to praise the company, which said it would add 100 jobs to produce PPE during the height of the pandemic.

Earlier this year the company was taken to task by its union, the Rochester Regional Joint Board of Workers United, for being delinquent in paying more than $3 million in health benefits for its workers. Gary Bonadonna, Jr., manager of the Rochester union office, did not return repeated calls to comment, but according to the Rochester Democrat & Chronicle newspaper, that situation was resolved earlier this month.

Hickey Freeman’s relationship with Rochester dates to 1899 when Jeremiah G. Hickey and Jacob L. Freeman, along with two other men, founded the company in that city.

But the plant is still struggling. According to sources, while the quality of the final product has not suffered, deliveries are routinely late due to the lack of staff. In addition, the factory recently raised its prices twice, sources said, prompting brands to start looking at alternatives.

Granovsky didn’t deny the price increases or that the factory has hit upon hard times, saying: “Our current struggles and the desire to find a buyer are related to a hangover from the pandemic and the loss of the Hickey Freeman license which Authentic decided not to extend or renew,” he said. He also acknowledged that prices have been increased since the pandemic and is set “seasonally, like every other factory and brand — each customer is different.”

But while Hickey Freeman is pivoting, Granovsky has a Plan B all set to go to replace the sales lost from Hickey — and it’s called Heritage Gold.

Starting later this year, the company will launch a new tailored clothing collection designed by Aliya Morehead, creative director and senior vice president of design and merchandising for both Samuelsohn and Hickey Freeman.

He described it as similar to Hickey but “refreshed in a modern way with upgraded product.” Prices will range from $1,995 to $2,495 for off-the-rack suits and $1,495 to $1,995 for sport coats.

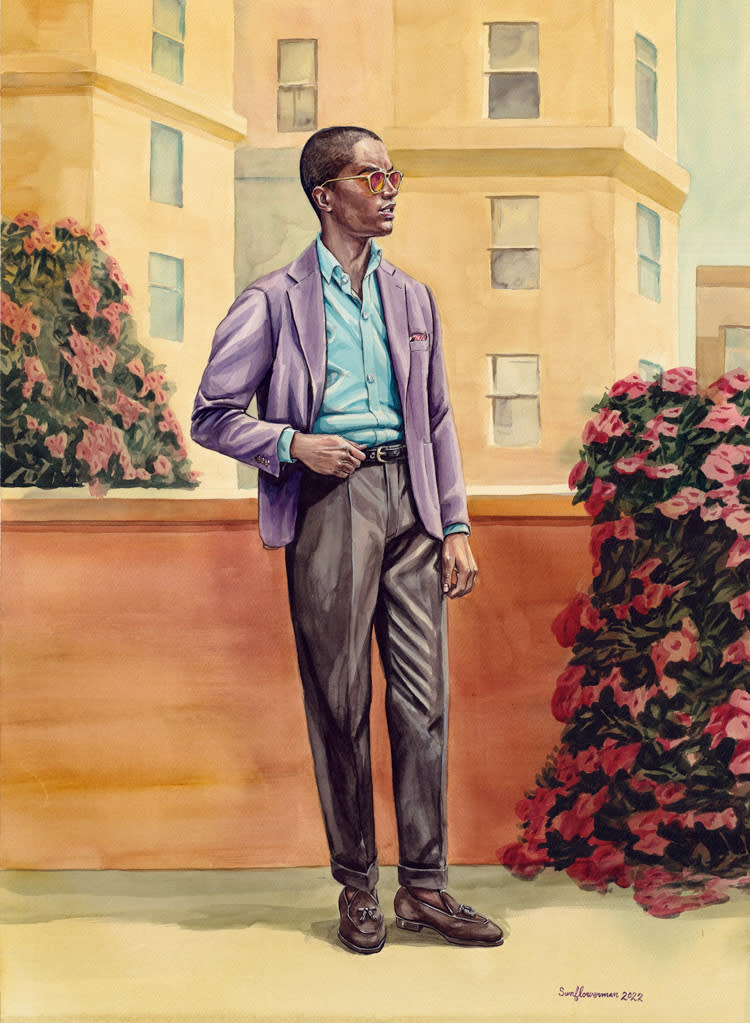

Morehead said the suits, which will be made in Samuelsohn’s Montreal factory, will be full canvas. Only made-to-measure will be offered for spring with off-the-rack coming in the fall. The design will be classic but updated with a variety of colors, patterns and textures. They will feature a curtain waistband, interior pocket inserts and lengthened horsehair to reinforce the canvas. For spring, shades of lilac, yellow and pale pink will be among the options. “People are gravitating to things they don’t have,” Morehead said.

And for fall, she said the company will “raise the bar with fabrics,” offering a cashmere program, high-grade wool and velvets in hues that range from the traditional dark tones to dusty rose sourced from the finest mills in Italy and elsewhere.

While the loss of the Hickey license after a decade was a blow, the shift to Heritage Gold appears to be working. “It’s been very successful,” Granovsky said. “We’ve managed to replace nearly all of the business we did with Hickey.”

Best of WWD