30 'Foreign' Cars That Are Made in America

In the global economy, “made in the USA” is a term with some gray area. Many of the world’s most popular overseas automakers, for example, assemble, finish, and ship their bestselling cars right here in the States. That's not likely to change even as more cars make the switch from gas to electricity: Toyota, for example, just announced plans to build a $1.29 billion plant in North Carolina that will make batteries for electric vehicles — and create more than 1,700 jobs — starting in 2025. Here are some not-so-foreign "imports" you may already know.

Related: 30 Iconic U.S. Brands That Aren't Made in America

The Toyota Motor Manufacturing Kentucky plant in Georgetown has assembled more than 11 million vehicles since 1988. The 8.1 million-square-foot facility builds not only the bestselling Camry, but also the Camry Hybrid, Avalon, and Avalon Hybrid. It employs more than 8,000 people and is capable of making 550,000 cars and 600,000 engines per year.

Related: The Bestselling Cars From the Past 40 Years

Toyota also makes the Avalon and Avalon Hybrid at the Georgetown plant in Kentucky, Toyota’s largest auto manufacturing plant in the world. A newly proposed investment of nearly $500 million will help add new technology and bolster its ability to help with electric vehicles.

For more fun auto stories, please sign up for our free newsletters.

The Toyota Motor Manufacturing Indiana plant in Princeton has been assembling cars since the first Tundra rolled off the line in 1998, although Tundras aren’t built there anymore. It supports 7,000 jobs and occupies 1,160 acres. Aside from the Sequoia, the plant builds the Highlander, Highlander Hybrid, and Sienna.

Related: These Cars Are the Most Likely to Surpass 200,000 Miles

Aside from the Sequoia, the Toyota plant in Princeton also builds the Highlander, the Highlander Hybrid, and the Sienna. The facility, occupying the equivalent of 70 football fields under a single roof, was built as part of a nearly $5 billion investment by Toyota, which made $3.7 billion in purchases in Indiana in 2018 alone.

The Toyota Tundra, as well as the Tacoma, come out of the Toyota Motor Manufacturing Texas plant in San Antonio. The plant sits on more than 2,000 acres of what was once Texas ranchland. Production at the facility began in 2006.

The San Antonio plant is also responsible for making the Tacoma, which, like the Tundra, is a pickup truck offered with several different trim packages. In 2008, the plant became the first Toyota facility to be awarded the JD Power Silver Award for Assembly Plant Quality in North and South America in its first year of operation. (Find out why the Tacoma is one of the Most Reliable Trucks of All Time.)

The 2 million-square-foot Toyota Motor Manufacturing Mississippi plant facility in Blue Springs employs 1,900 Mississippians. They build 170,000 Corollas every year, the only vehicle to come out of the 1,700-acre plant. Production started there in 2011 after an investment of nearly $1 billion.

In 2020, Honda made its 20 millionth car in Ohio. The Honda of America Manufacturing Marysville Auto Plant has been making vehicles since 1982, and today the 4 million-square-foot plant assembles not just the popular Accord, but also the Acura ILX and TLX. It is the heart of Honda’s Ohio operations.

The Marysville plant also assembles the Acura ILX, of Honda’s luxury brand. The ILX is what the automaker calls the “gateway vehicle to the Acura lineup,” an entry-level luxury car that serves as a bridge between the more affordable Honda offerings and the pricier Acura lineup.

The Acura TLX also comes out of the Marysville plant, billed as a vehicle that represents a blend of the Acura TL and TSX. With nearly 40 years of continuous operation, the Marysville plant exports Honda and Acura cars to more than 100 countries.

In addition to the Marysville plant, the Honda CR-V also comes out of another plant in Ohio, the East Liberty Auto Plant, as well as a plant in Greensburg, Indiana. The 2.1 million-square-foot East Liberty facility has been in operation since 1989.

The East Liberty Auto Plant is the sole producer of the Acura RDX, a premium SUV. Since its inception in 1989, the facility has made more than 4.5 million vehicles under the Acura and Honda brand names.

Honda Manufacturing of Alabama in Lincoln supports 45,000 jobs and has a $12 billion economic impact every year. It builds not just the Honda Odyssey, but also the Honda Passport, the Pilot, and the Ridgeline.

The Lincoln plant builds not just the Honda Odyssey, but also the Honda Passport, a popular midsize SUV. The facility’s economic impact represents a full 5.4% of Alabama’s GDP. In 2018, it paid more than $200 million in taxes. Honda also makes the Pilot and Ridgeline there.

Nissan North America has its headquarters and its highest-volume North American production plant in Smyrna, Tennessee. It has a production capacity of 640,000 vehicles a year. The Smyrna plant makes the Leaf, Maxima, Murano, Pathfinder, Rogue, and the Infiniti QX60.

Nissan also builds its popular Pathfinder SUV at the Smyrna facility. The plant began operations in 1983 and today holds the distinction of being North America’s highest-volume vehicle assembly plant, a title many Americans might assume was held by one of the Detroit automakers.

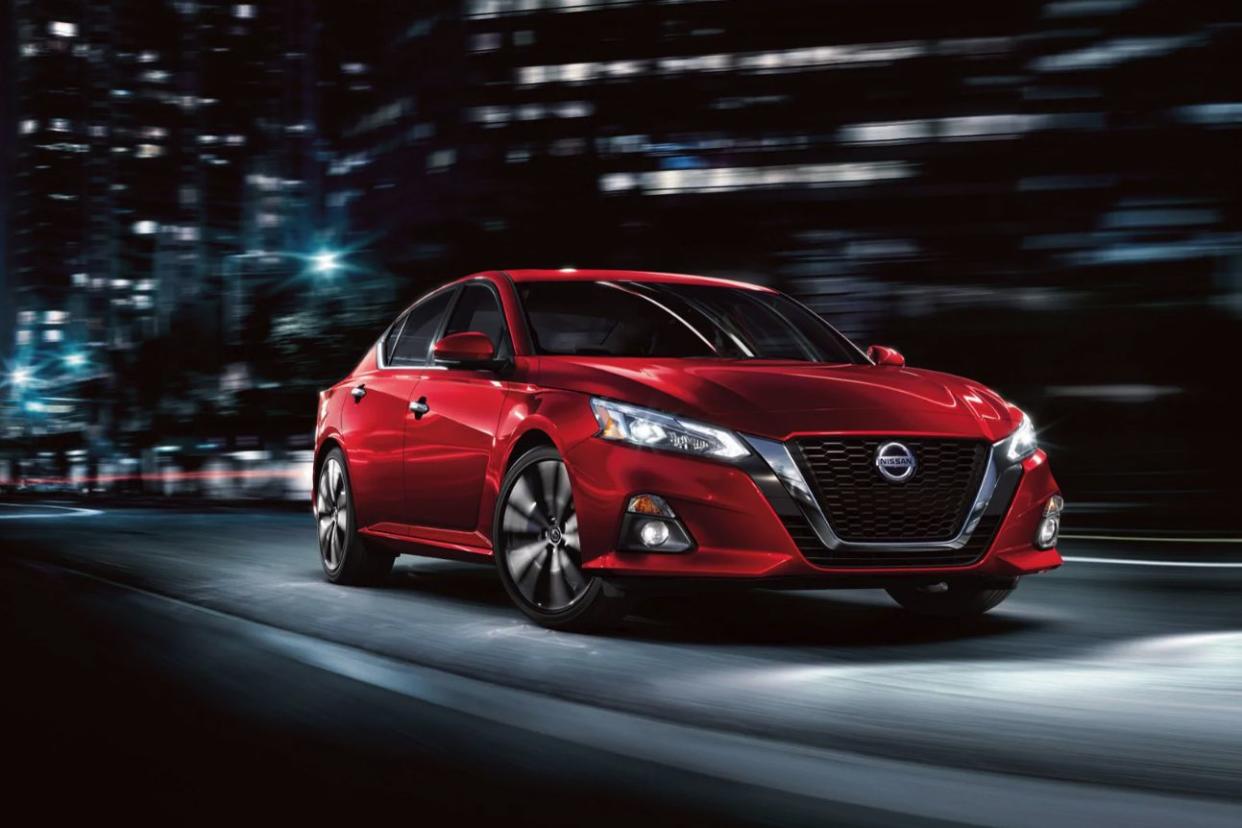

Nissan’s other major American plant is the one in Canton, Mississippi, which is capable of making 450,000 vehicles yearly. Another plant in Decherd, Tennessee, assembles powertrains. The Canton plant makes the the Altima, Frontier, and Titan.

Subaru of Indiana Automotive in Lafayette is home base for Subaru’s North American production arm. The Subaru Outback, Legacy, Impreza, and Ascent are all assembled in the plant, which made more than 367,000 vehicles in 2020, up from 4,087 during its initial run in 1989. The 3.65 million-square-foot facility sits on 820 acres and includes 16.85 miles of conveyors.

Subaru also builds the Legacy at the plant in Lafayette, an enormous facility that includes a 2-mile test track and a 156-acre motor pool. It’s home to a 10,500-square-foot technical training building and a nearly 1.4 million-square-foot container yard.

Hyundai Motor Manufacturing Alabama is in Montgomery. The 2 million-square-foot, $1.7 billion plant is the first of its kind in the United States for the Korean automaker, and it supports more than 3,000 jobs. The Hyundai Elantra is made there, as is the Sonata, Santa Fe, Tucson, and new Santa Cruz Sport.

Hyundai also makes the five-passenger Santa Fe SUV at the facility in Montgomery. In 2007, the facility earned a coveted highest certification by the International Automotive Task Force.

Kia Motors Manufacturing Georgia is in West Point, and when the $1.1 billion, 2,200-acre site opened in 2006, it was one of the largest single foreign investments in Georgia history. It has a capacity of 340,000 vehicles a year and supports 14,000 jobs when suppliers are included.

The Kia K5, which replaced the better-known Optima, is a midsize sedan, and it, too, comes out of the West Point plant. It’s Kia’s only manufacturing facility in the United States — and the only automaker of any brand in the entire state. It’s responsible for supplying 940 dealerships in the U.S. and Canada.

Kia builds not only the Sorento and K5 but also the popular and highly rated Telluride in West Point. The company has built more than 2.7 million vehicles there since the facility opened in 2006. The plant operates 24 hours a day and 90% of the vehicles it makes wind up in U.S. dealerships — that’s 40% of all Kia sales in the U.S.

Tennessee’s Volkswagen Chattanooga Assembly Plant sits on 1,400 acres, includes 3.4 million square feet of under-roof space, and employs 3,800 people. Volkswagen makes the Passat there, as well as the Atlas.

Related: The 22 Most Popular Volkswagens of All Time

VW also builds the Atlas at the Chattanooga Assembly Plant. In fact, the 100,000th Atlas was assembled there in 2018. It’s a unique facility that includes on-site protected wetlands that serve as a home to plant and animal habitats. Its 33,000 solar panels generate about 12 million kilowatt-hours of energy every year.

Mercedes-Benz U.S. International in Tuscaloosa, Alabama, is a completely unified plant, with assembly, painting, body, shipping, and administration all under one roof. The facility, opened in 1995, is the largest Mercedes-Benz plant outside Germany, employing 3,800 people directly and 10,000 indirectly. The Mercedes-Benz GLE Coupe and SUV are assembled there, as are the GLS-Class and C-Class models.

Mercedes-Benz GLS-Class luxury SUVs come out of the Tuscaloosa facility in Alabama. The plant runs on a streamlined production philosophy that it calls “just in time” manufacturing, allowing only two hours’ worth of inventory to be stocked at any time to prevent waste and backlog. When new inventory is needed, an automated system orders it for immediate delivery.

Mercedes also produces its C-Class vehicles at the Tuscaloosa facility. The plant is the first major auto manufacturing facility in Alabama, and the company has invested more than $6 billion in the state. It’s currently investing more than $1 billion in new capital to begin the production of all-electric passenger cars.

The BMW US Manufacturing Company plant in Spartanburg, South Carolina, makes the BMW X3, X4, X5, X6, and X7. The massive 7 million-square-foot plant makes more than 1,500 vehicles daily for a total of more than 5 million cars made overall. It employs more than 11,000 people directly onsite.