Ever seen how beer cans get printed? Watch how two Austin brothers do it on a massive scale

Analysis paralysis is a familiar feeling for any craft beer enthusiast. Standing in a liquor store or gas station, staring at the racks of beer, desiring to try something new but you just can’t quite figure out what you really want.

After an unknown number of minutes and several dancer-like sidesteps to allow other customers to pass down the aisle, you settle on a new variety because the packaging is enticing. Grabbing the six-pack and hoping for the best, you’re on a new adventure with a new beer.

Graphic design is a critical marketing tool for beverage makers of all kinds. You shouldn’t judge a book by its cover, but with a beer or seltzer or hard kombucha – that's exactly what designers want you to do. Their dazzling designs and bright colors are all to lure in someone looking to expand their horizons. Businesses can soar or flop based on how well they are able to grow sales in retail settings.

Marshall and Ryan Thompson, a pair of entrepreneurial brothers, aren’t brewers or drink makers. They don’t sell beer or other beverages. You likely won’t even recognize their business name, but anyone who has shopped for beer in Austin is unknowingly familiar with their work.

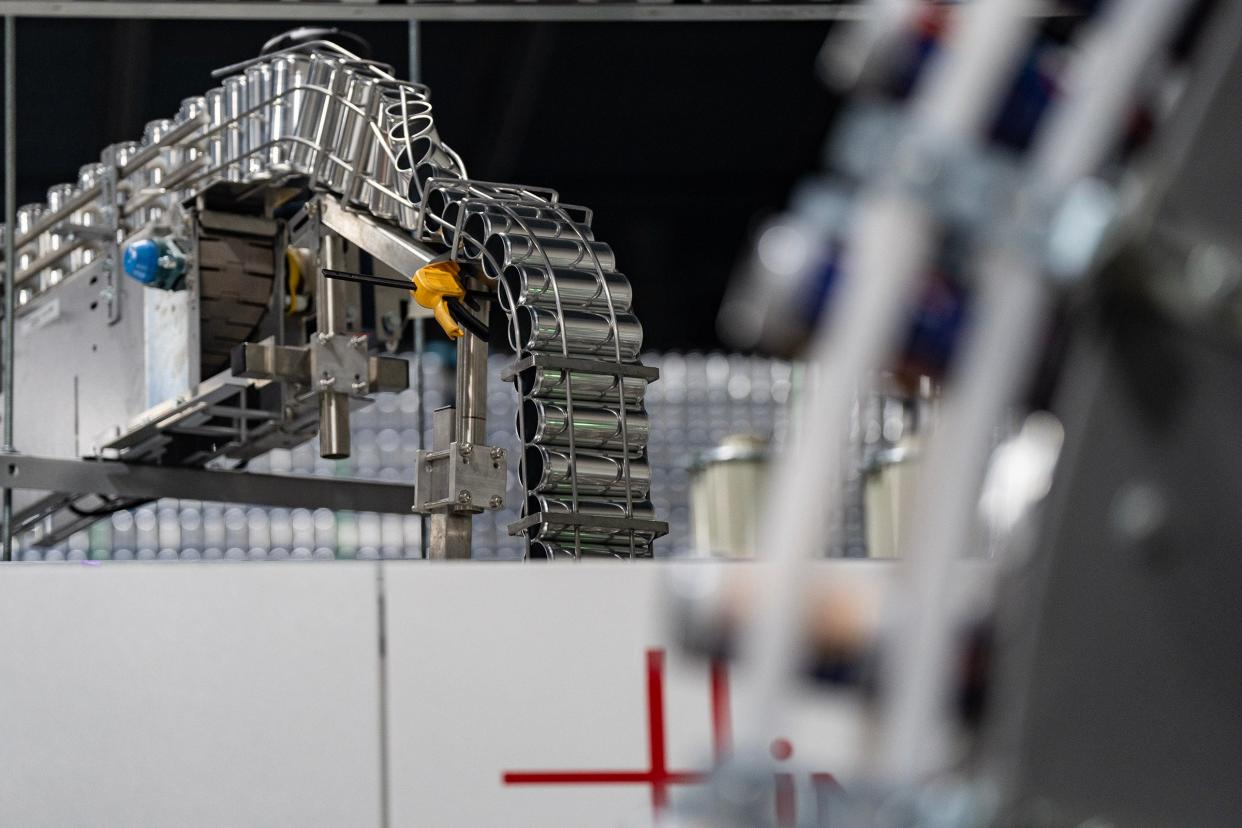

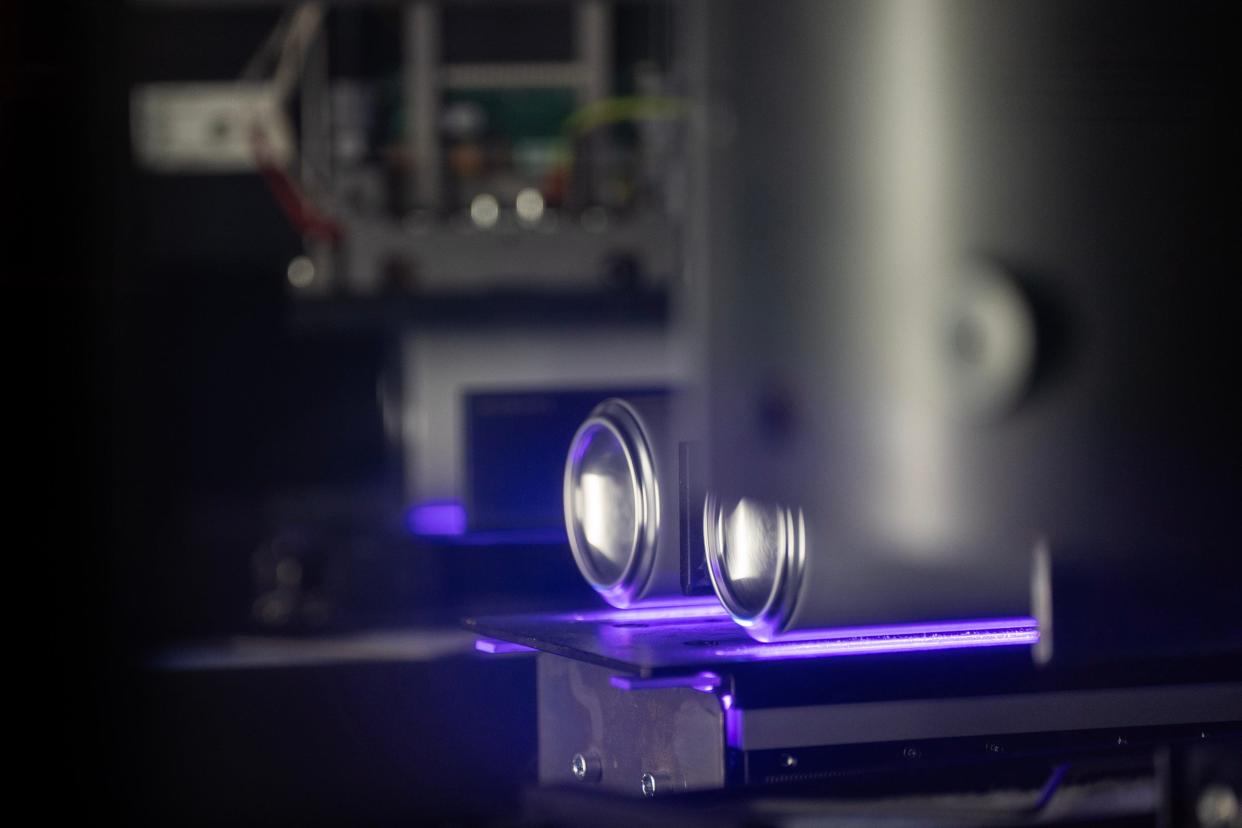

That’s because Canworks, the business the two launched in 2021 prints hundreds of thousands of beverage cans every single day from its warehouses in Austin and San Diego. The brothers use high-tech printers to directly print any design with any color onto near any cylindrical object – with beverage containers being the most prevalent.

Canworks doesn't make the designs, but rather allows the client to provide the artwork and prints it in high resolution directly onto the can. It works functionally the same way an office printer does on paper – except you end up with cans that get filled with your favorite brew instead of yet another boring report to be tossed in the trash.

It's a different process than what many drink makers use. Cans are often labeled using stickers, or shrink-wrap plastic, all which add waste to the can and make it harder to recycle, Marshall Thompson said.

Canworks cans can be found in breweries, convenience stores and grocery stores spread across Texas and the rest of the country. The business is expanding, with a new facility opening up soon in Atlanta. When that facility opens, Canworks will be able to produce half-a-million cans per day.

But its success wasn’t always so certain.

A ‘hair-brained idea’ goes nowhere, but a viable business emerges anyway

Marshall Thompson thought he had a great idea. He wanted to sell canned water, but soon realized he didn’t have the experience needed to carve into a marketplace that was becoming dominated by other brands.

“In hindsight, it wouldn’t have worked out,” Marshall Thompson said.

But during some initial exploration into the business idea, he noticed something he ultimately used to dream up Canworks. It’s difficult to obtain small batches of cans, he said, and if you do, the stickers and shrink wrap used for labels can negate the recyclability of aluminum cans.

An avid outdoorsman who loves snow skiing, hiking and fishing – Marshall Thompson was intrigued by the idea of providing a service that allowed for beverage makers to print directly on cans instead.

“I kind of pivoted at that point and thought, ‘Wow, that would be really interesting, just to do that instead of actually having a brand,’ you know?” Marshall Thompson said. “So long story short, I called Ryan up and said, ‘Hey, I think I’ve got something interesting on our hands.’”

In typical brotherly fashion, Ryan Thompson has never been afraid to tell Marshall what he thinks.

“My brother’s always had a penchant for ideas, and I don’t always love his ideas, which I’ve told him,” Ryan Thompson said.

But this one was different.

Marshall Thompson was very intrigued by the manufacturing angle, his brother said. And Ryan Thompson loved that this idea fell at the center of manufacturing and beverages.

“I’d always wanted to so something more entrepreneurial,” Ryan Thompson said.

Marshall Thompson decided to see if there would be a market for this kind of service by reaching out to several dozen breweries.

“Most of it was just cold calls and I basically said, ‘If I could provide this service and this type of can in this kind of lead time and with this type of artwork capabilities, would you be in?’” Marshall Thompson said. “I think 100% of them said, ‘Yes,’ and so at that point I was like, ‘We got a business here.’”

Both brothers were sold on the idea. There were potential clients and demonstrated demand for the service. But the biggest hurdle turned out to be getting a bank on board.

Securing a loan was nearly disastrous

Convincing a bank to loan the pair several million dollars to purchase their first industrial printer proved extremely difficult. The brothers went through somewhere between 15 to 20 banks without luck, Ryan Thompson said.

Finally, they had a loan secured. The brothers quit their jobs (Marshall worked in commercial real estate and Ryan was in management for consulting in the tech sector), and were ready to roll.

Then that bank backed out.

That was a moment of real fear, for Marshall Thompson. Having quit their jobs and seemingly nowhere to go forward, he wasn’t sure the business would ever launch.

But a reference was made to one more bank, and that proved the winner. A loan was secured and about seven months later the brothers had their first printer, Ryan Thompson said.

Business has boomed and Canworks has helped many small businesses in the process

In the years since, Marshall and Ryan Thompson have opened a San Diego facility, where Ryan now lives. They are opening an Atlanta facility later this year, at which point they will have the capacity to print designs onto 500,000 cans per day.

Those cans are printed before they are filled with product, and they are shipped to brewers or beverage makers across the country where they are filled and then sold.

Ryan Thompson estimates Canworks has printed products for nearly 400 different businesses, and the company has expanded to employ about 60 full-time individuals.

But the ability to custom-print small batches of cans has played a tremendous role in the ability for other businesses, brewers and beverage makers alike, to get their products in the hands of consumers.

Austin-based Pinthouse Brewing is one of those clients that benefits from the work of Canworks. The business is constantly experimenting with new beers and is known for its signature can style. The customization offered by Canworks allows Pinthouse to put out so many of its experiments into cans that can be purchased outside of its taprooms, said Jacob Passey, Pinthouse’s director of brewery operations.

“We wouldn’t be able to do what we do with a bigger vendor,” Jacob Passey said.

The Thompson brothers love being able to work with clients like Pinthouse and Passey. They also love seeing their work in stores.

“I love going into stores and seeing cans that we made, or taking my daughter to the farmers market and seeing kombucha cans we made,” Ryan Thompson said. “There’s a deep satisfaction in seeing that.”

“From a personal side it made a lot of sense, from a professional side it made a lot of sense and it’s been the right decision,” Marshall Thompson said.

“Personally, and I think Ryan would speak to this some too, but ... we got into this because we were beer fans,” Marshall Thompson said. “There’s something about going to a craft brewery or just going into H-E-B or the grocery store and picking out your favorite label.”

Cheers to that.

This article originally appeared on Austin American-Statesman: Austin beer entrepreneurs make business with direct-to-can printing