America Celebrates Manufacturing's Cool Factor

By Nicole Schuman

In cities where the industrial economy once blossomed -- Detroit, Chicago, Cleveland, Pittsburgh, Buffalo -- decaying rusty shells of abandoned steel, automobile and grain plants line the highways and byways. These shuttered factories tell the tale of a bygone era of manufacturing, and have led the image of the industry for many years.

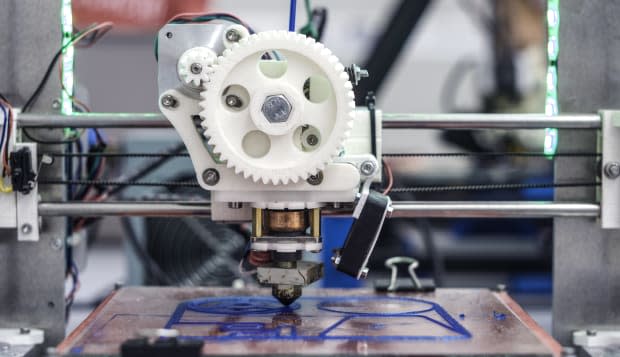

Many Americans do not realize that the manufacturing industry in America is experiencing a renaissance, and for some companies, it never even went away. With the advent of technology, 3D printing and the desire for quality over quantity -- U.S. businesses are answering the call to bring jobs back from overseas and create in America's backyard.

On Friday, Oct. 3, 2014, more than 1,500 companies from the U.S., Canada and even Puerto Rico are participating in Manufacturing Day. Factories and organizations will host various events: facility tours, workshops for students, and open houses to show solidarity in the industry and showcase modernization and local economic importance.

"By introducing local communities to their manufacturing sector and demonstrating the contribution that manufacturing makes to the local economy, we can ensure a better future and way of life for our children and grandchildren, said Ed Youdell, president and CEO of the Fabricators & Manufacturers Association and founder of Manufacturing Day. "Our future depends on our ability to strengthen and advance this vital sector of the nation's economy."

The Value of Manufacturing

Manufacturing has always been a solid source of income for many families. Because wages in the U.S. reward these hard-working positions, many companies have moved operations overseas -- paying a fraction of a homeland salary. But cheaper does not always equal better.

The average yearly salary of a manufacturing worker is over $77,000, much higher than the U.S. median average of $48,872. The manufacturing industry supports over 17.4 million jobs in the U.S. and comprises 12 percent of the U.S. GDP. These jobs not only contribute to building products and infrastructure, but economically support local shops, restaurants and entertainment.

The surprising part is manufacturing companies cannot fill these well-paying jobs fast enough, due to misconceptions about the sector. Eighty percent of companies cannot find the skilled workers they need.

> These manufacturing jobs are open now

"Manufacturing Day is critical to resolving the skilled labor shortage in manufacturing," said Patricia Lee, Director of Marketing for Fabricators & Manufacturers Association Int'l®. "Some people think we don't make anything here in the U.S. anymore, and yet nothing could be farther from the truth. This annual opportunity for manufacturers to open their doors, invite the community in, and share information about what they do and the types of skilled employees they need is critical to resolving this labor crisis which will only accelerate as more and more Baby Boomers retire."

The Growth of Manufacturing Day

A localized, grassroots effort has helped to quickly grow the Manufacturing Day movement. Not only factories, but chambers of commerce, regional associations and local economic development groups quickly recognized the unique opportunity to do something in each community.

In 2012 Manufacturing Day started with 220 events, with 247 manufacturers in 37 states participating.

A year later the event grew over 100 percent with 834 events in 48 states with more than 35,000 attendees. This year growth will continue with 1,500 events in the U.S., Canada and Puerto Rico including one with a visit from President Barack Obama.

The numbers may be impressive to the public, but for Manufacturing Day organizers, there is still a long way to go. The 10-year-goal of the organization is to grow to the point where 75 percent of all manufacturing plants in America participate -- and more than 175,000 event locations.

It's Not Just Nuts and Bolts -- It's The Future

Vintage images of manufacturing include conveyor belts, assembly lines, smoke and dirt, but many things the U.S. makes have nothing to do with nuts and bolts. Companies include golf club makers, high-tech 3D printers, artisanal yogurt and massaging flip flops.

At first-year participant Taylormade Golf Company in Carlsbad, Calif., visitors will be taken to the production floor to walk through a golf club assembly process.

"At the heart of manufacturing there is innovation," said Rosie Scannell, representative for Taylormade, which was founded in 1979. "We are excited to open our doors and invite the community to see first-hand how we push the envelope and create products that will inevitably help golfers of all skill levels reach their potential."

Each of these companies takes great pride in what they create, and the process of creating it. For many, the specialized knowledge of their field is a learned skill; one that has taken many years to master. For many companies, the best part of Manufacturing Day will be visits from students and showing them the potential of industrial careers.

"It provides students a first-hand chance to learn about real career opportunities that are available, and we're hoping to inspire a new generation of manufacturers," said Heather Krugler, representative for Super Steel, LLC in Milwaukee, Wis.

Kathy Brewster of DBA Brewster Washers in Fairfield, N.J. notes the importance of "seeing is believing" to students.

"We want to show our youth that manufacturing is and has been a part of our country's history and needs to grow; that it is not a "dirty job" and that there is a future."

For a company like R&D Plastics, LLC in Hillsboro, Ore. a future employees may walk into the plant on Manufacturing Day. High school student tours are organized by the Greater Hillsboro Area Chamber of Commerce.

"We hire entry level (no experience) machine operators and train and promote within the company for manufacturing support roles," said Charlie O'Bosky, general manager. "Manufacturing Day is a great chance to promote our company as a career opportunity to young people."

And for a young company like 3D Parts Manufacturing LLC in Indianapolis, Ind., the industry has taken on a "cool" factor.

"I graduated with engineering degree in 1975," said Kim Brand, president. "Integrated circuits, microprocessors and software were cool then. Manufacturing is cool now. Advanced manufacturing with 3D printers and lasers make it technically challenging and interesting for smart kids. As an employer and entrepreneur I want there to be more motivated people to hire."

Nicole Schuman is social media editor of This Built America.